What Is In-Mould Labeling (IML)?

What Is In-Mould Labeling (IML)?

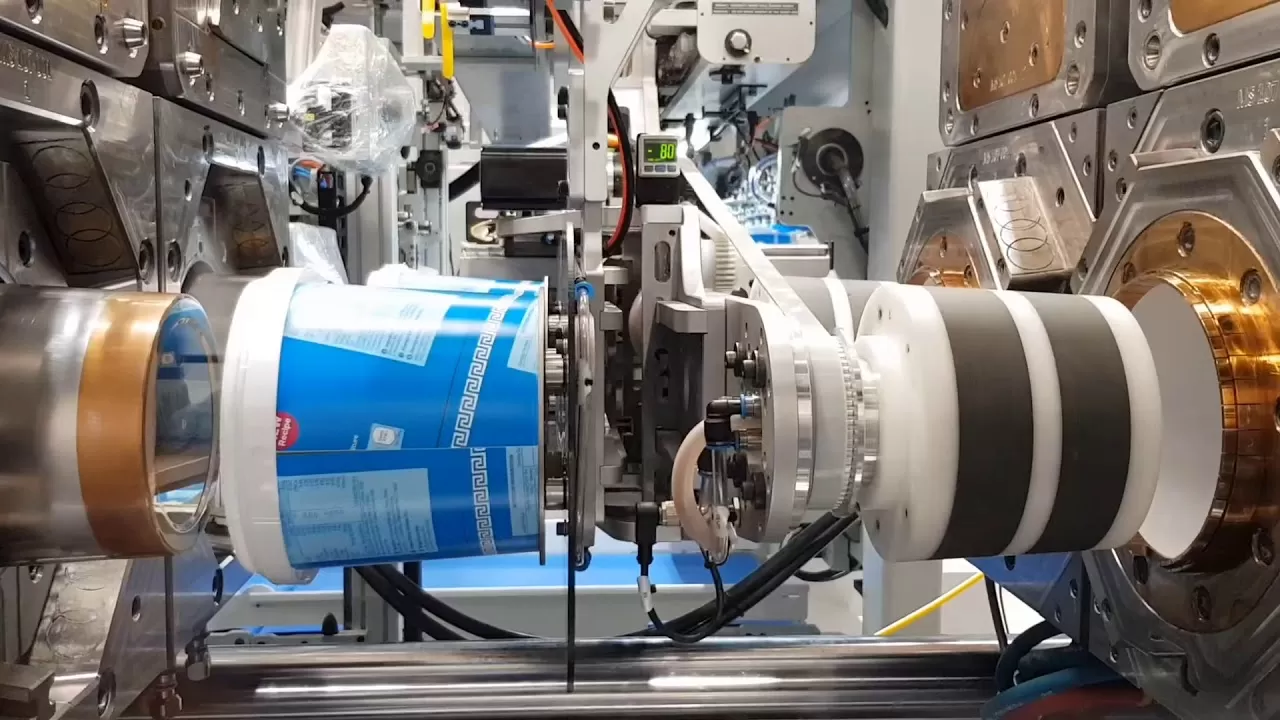

In-Mould Labeling (IML) is a modern printing and packaging technology in which the printed label is placed directly into the injection mould. When molten plastic is injected, the label fuses seamlessly into the product surface, creating a fully integrated, ultra-durable, premium-looking finish.

By combining printing and molding in a single step, IML has become the leading solution for food packaging, cosmetics, household goods, and industrial containers.

How IML Works

The IML process includes three main stages:

Label preparation

The label is printed on high-quality PP/PE film that is recyclable, heat-resistant, and safe for food packaging.

Label placement inside the mould

A robot or trained operator places the label into the mould cavity in a precise fixed position.

Injection molding – forming a one-piece product

Molten plastic is injected into the mould → The label bonds permanently to the product → The result is a ready-made plastic packaging with a built-in label.

The product comes out of the mould perfectly finished—no post-printing required.

Advantages of IML

Superior aesthetics

-

Vibrant, high-resolution colors

-

No peeling, smudging, or scratching

-

Full 360° printing capability

Exceptional durability

-

Water-, impact-, and heat-resistant

-

UV-resistant, suitable for outdoor storage

-

Suitable for cold storage or freezing

Cost-effective for mass production

-

Printing + molding in one step

-

Ideal for automated production lines

-

Compatible with robotic label placement

Eco-friendly and safe

-

Labels and containers are both PP → 100% recyclable

-

Food-contact safe

Limitations of IML

-

Higher upfront investment in molds, robots, and label materials

-

Not ideal for very small orders

-

Requires specialized injection molding machines and trained technicians

Common Applications of IML

Food packaging

-

Ice cream tubs

-

Yogurt cups

-

Nut and snack containers

-

Butter/margarine tubs

-

Premium plastic drink cups

Household products

-

Trash bins

-

Storage boxes

-

Rice containers

-

High-end plastic organizers

Cosmetics & pharmaceuticals

-

Tablet containers

-

Cream jars

-

Functional food packaging

Industrial packaging

-

IML paint buckets

-

Chemical or agricultural plastic pails

Types of IML Labels

-

IML PP (Polypropylene): most popular, ideal for injection molding

-

IML PE (Polyethylene): used for flexible or impact-resistant products

-

Metalized IML: metallic premium effect

-

Transparent IML: high-end appearance, allows product visibility

IML vs. Heat Transfer Printing vs. Traditional Printing

| Technology | Durability | Aesthetic Quality | Cost | Best Use |

|---|---|---|---|---|

| IML | Very high | Excellent, seamless | High | High-end packaging, mass production |

| Heat Transfer Printing | High | Beautiful | Medium | Seasonal packaging, plastic boxes, household items |

| Screen/UV Printing | Medium | Fair | Low | Simple designs, small-scale production |

Why Businesses Choose IML at HyunTech Holdings

HyunTech Holdings is a leading provider of IML printing – heat transfer printing – plastic film printing in Vietnam, offering:

High-standard IML factory in Hung Yen

-

Japanese & European IML printing systems

-

Robotic label pick-and-place for precision and speed

Premium design & print quality

-

3D mockup support

-

High color accuracy and long-lasting adhesion

Wide range of label materials

-

PP IML, metallic, transparent

-

Compatible with all injection molding systems

Competitive pricing – on-time delivery – print warranty

Ideal for F&B, FMCG, cosmetics, pharmaceuticals, and industrial brands.

Conclusion

In-Mould Labeling (IML) is a high-end, durable, visually striking labeling technology that is becoming the top choice for brands aiming to elevate their packaging. With strong production capacity, quality standards, and design expertise, HyunTech Holdings is a trusted partner for professional IML printing.

👉 HyunTech Holdings – Print the Future | Shaping the Future of Printing

HYUN-TECH HOLDINGS JOINT STOCK COMPANY

Head Office:

Lot BT11, Eurowindow River Park Urban Area, Dong Anh, Hanoi, Vietnam

HyunTech Hung Yen Factory:

312 Nguyen Van Linh, Duong Hao, Hung Yen

Heat Transfer Processing Factory:

Doai Village, Vinh Thanh, Hanoi

Hotline: 0332.837.260 – 08888.1.3333

Website: https://hyuntech.com.vn

Email: contact@hyuntech.com.vn

Facebook Fanpage: https://www.facebook.com/hyuntechprint

YouTube: https://www.youtube.com/@Hyun-Tech

#IML #heattransferprinting #printplastic #inmoldlabel #hyuntech #heattranfer #manufacturingfactory #QA #OEM #HyunTechHungYen